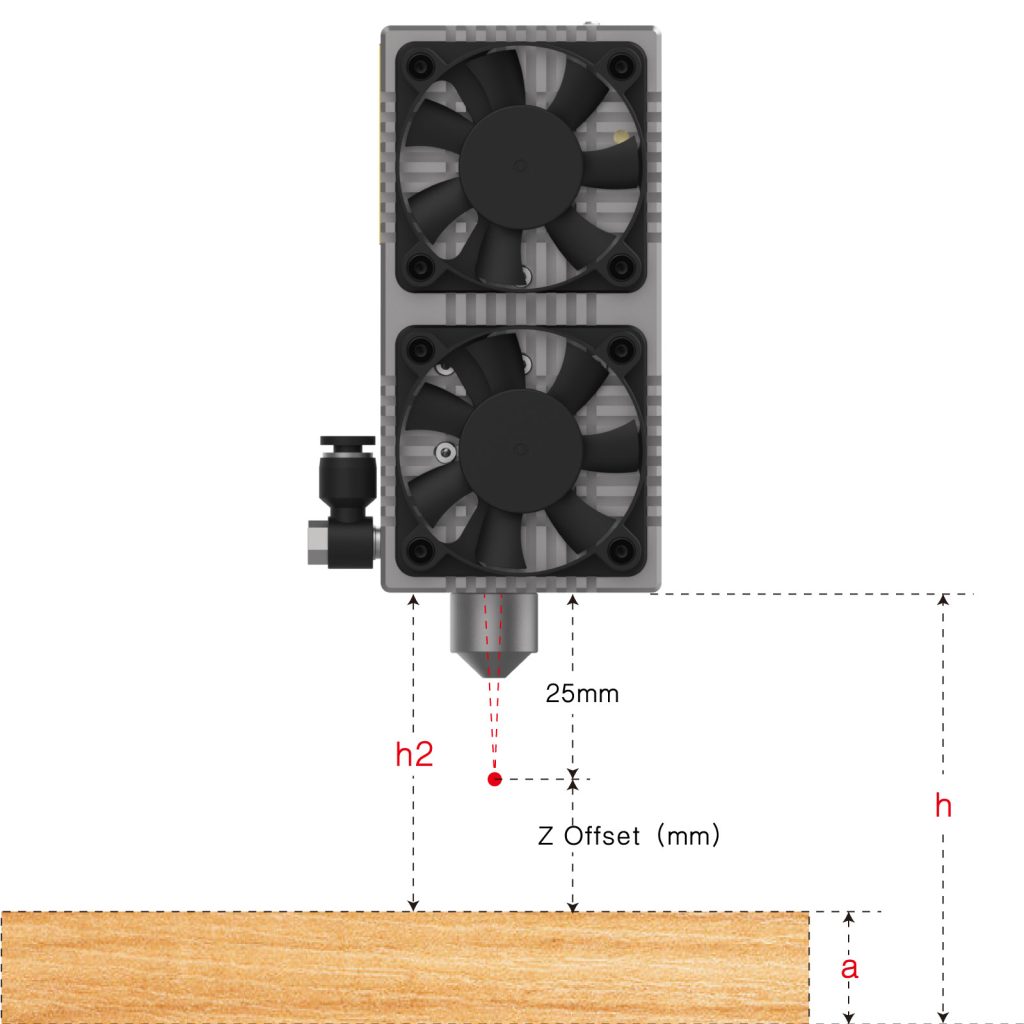

How to Focus

a) Z Offset (mm) = h2 – 25

b) Z Offset (mm) = h – 25 – a

Z Offset < 45mm(NEJE Max 4)

SPECIFICATION

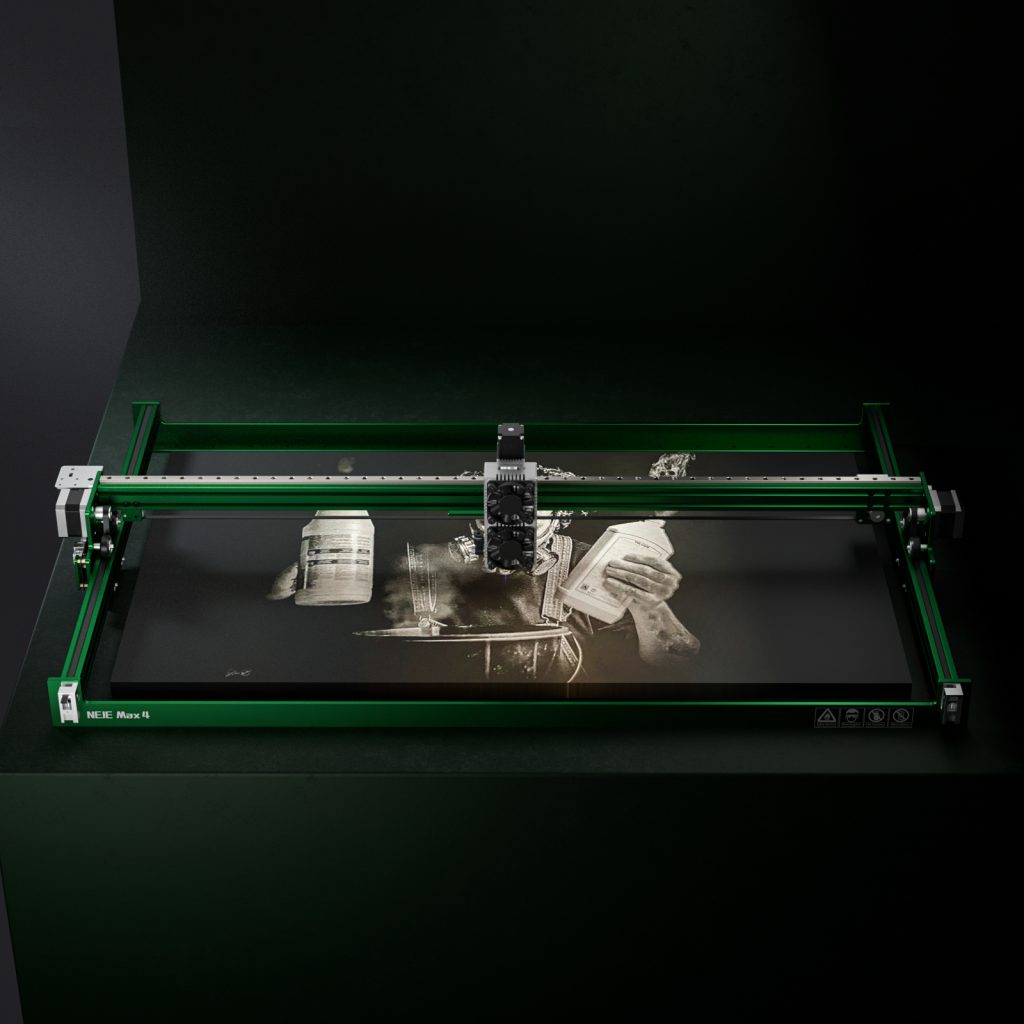

NEJE 4 Max E80 Laser Engraver

| Optical Power: | Pulse 24W, CW 21W |

| Frame Size (L – W – H): | 970x582x60mm |

| Working Area( X – Y): | 750 x 460mm, Extends to 750x1030mm |

| Drive Accuracy: | XY-axis repeat positioning accuracy 0.01mm, Z axis 0.001mm |

| Number of Controllable Axis: | X,Y,Z,A four axis |

| Input Voltage: | 24V, Match according to module voltage |

| Limit Switch: | Yes, both XYZ |

| Max Move Speed: | 750mm/s |

| GRBL Offline Control: | Yes |

| M7,M8,Door Extension: | Yes |

| App control: | Yes |

| MEMS: | Yes |

| NEJE Software OTA Upgrade: | Yes |

| Vertical Carving: | Yes(90°) |

| Systems Support: | Win 7/Win 8/Win 10, Android, iOS, ipadOS, macOS |

| File Format Supports: | .GC/SVG/DXF/JPG/JPEG/PNG/BMP/TIF/CR2/AI/SC/etc. |

NEJE E80 Laser Module

| Focus Size: | 0.6×0.6mm |

| Input: | 24V 5A |

| Interface: | 4pin PH2.0 + ( 2pin DC 24V extra power) |

| Weight: | 600g |

| Number of Diodes: | 4 |

| PWM Input: | VPP(3.3-24V), Recomend 1KHz, |

| Quiet Design: | Drive the built-in control ic, judge the working state and adjust the fan work |

| Adapter Pluga: | 5.5 2.1 port |

| Working Voltage: | DC 24V |

| TTL&PWM Modulation: | YES. Compatible with Both TTL & PWM Modulation |

| Input Interface: | PH2.0-4Pin (+,-, PWM/TTL, Temperature), 3Pin (+,-, PWM/TTL) , 2Pin+2Pin (+,-) + (PWM/TTL,-) |

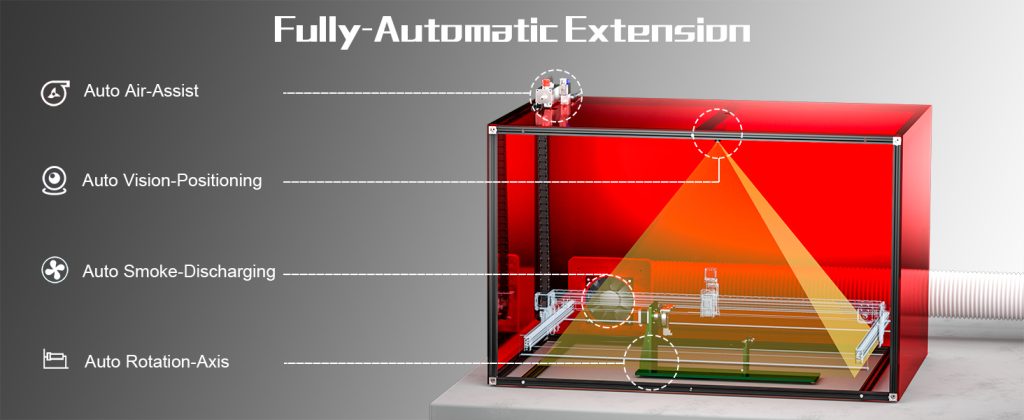

FEATURRE

- Hybrid compression technology makes the focal point of NEJE E80 0.1×0.1mm, and the power density reache 6666W/mm², Compared with *tool 40W module,power density:5000W/mm² (0.8×0.1mm,8xLD,Current highest power) , the performance of E80 is 35% higher than the 40W module. Due to the extremely strong power density and optical design, NEJE E80 has more excellent performance when the power is halved. Compared with other 20W modules, NEJE E80 has great advantages in terms of lifespan and performance.

- 750 (X) * 460 (Y) * 45 (Z) mm working area, Y-axis track can be extended to 1030mm, in 3-dimensional space, it can support simultaneous processing of various items with different thicknesses. Compared with the ordinary 400x400mm frame, the work efficiency increases by 400%

- The problem of high power module fire has been solved revolutionary. Through the Z-axis layer-by-layer cutting mode and E80’s unique optical cutter design, it can safely cut 17mm pine wood without fire even without air assist

- The cutting efficiency is increased by 200%, which is higher than that of 40W (optical power) module The perfect optical design of NEJE E80 makes the E80 focus power density and beam angle reach a perfect state by optimizing the beam structure and adopting more complex manufacturing technology.When the power 1 time smaller than the 40W module, it can even reach the same cutting speed, and the notch is smaller, avoiding the trapezoidal and XY asymmetry problems.

- You can transmit Lightburn working files and control the device wirelessly.NEJE uses the combination of built-in virtual instruction mode and Bluetooth technology to transmit and control professional multi-layer gc files wirelessly through NEJE. NEJE retains the “One Key Start” function, eliminates the backward sd card mode, and allows the device to work without occupying your computer.

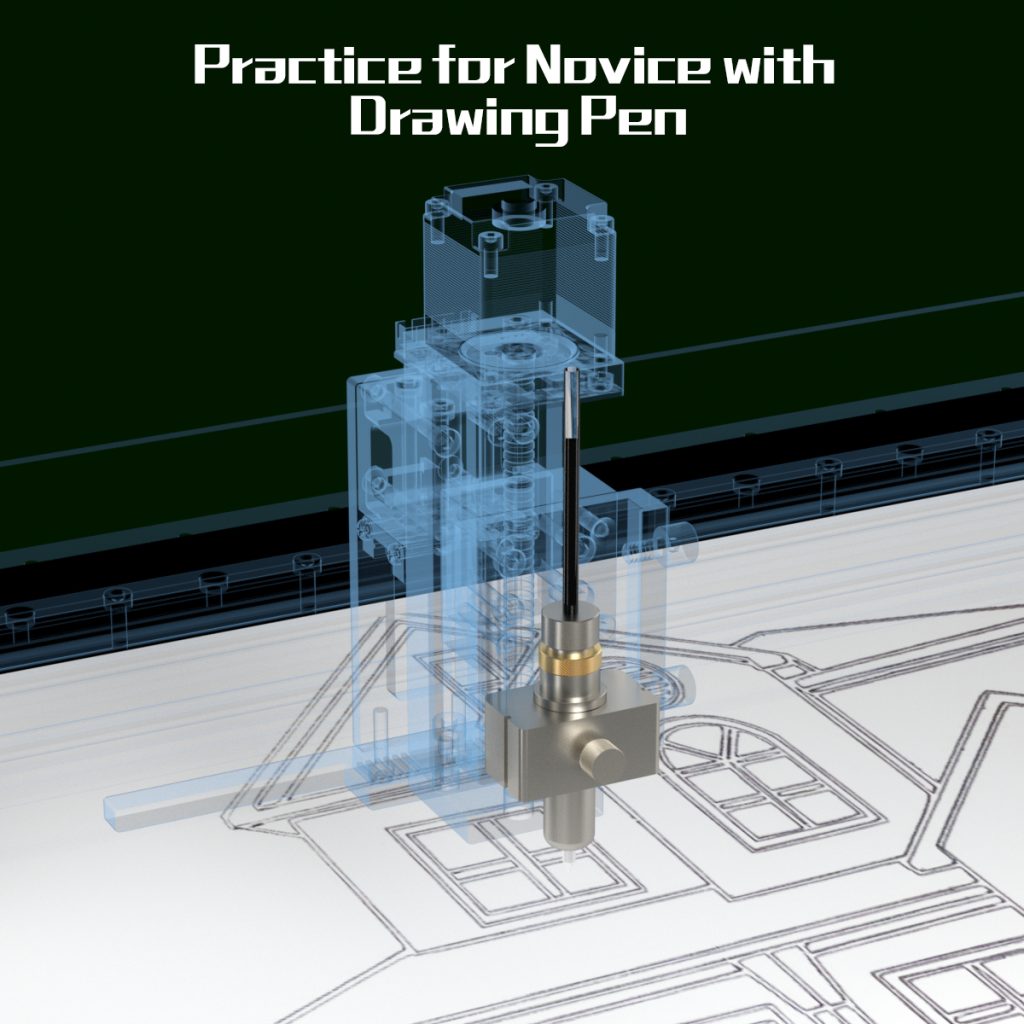

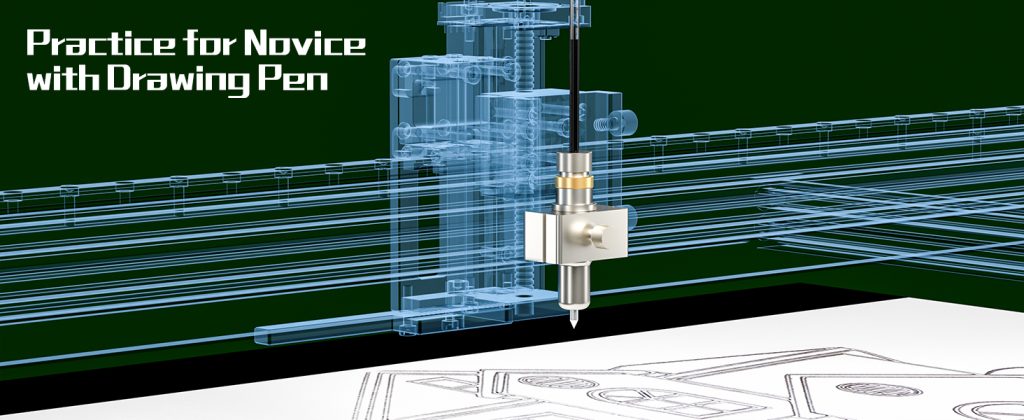

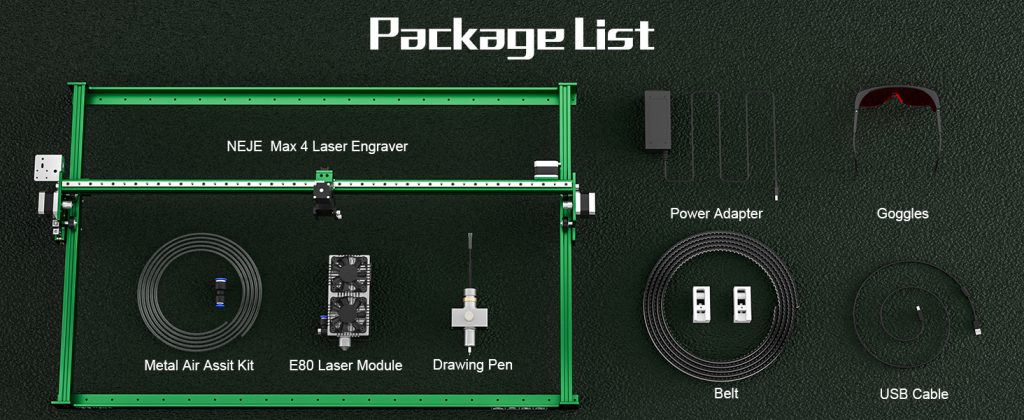

- The drawing pen is included in the package. It can draw images, which can let children and beginners experience the fun of CNC. It can also draw paths with the drawing pen, and preprocess advertising materials that cannot be processed by laser wavelength.

- The processing speed is 24000 mm/min,it’s faster than 400 mm frame’s peak speed. The combination of Max 4 and NEJE high-performance module makes the efficiency reach an excellent state.

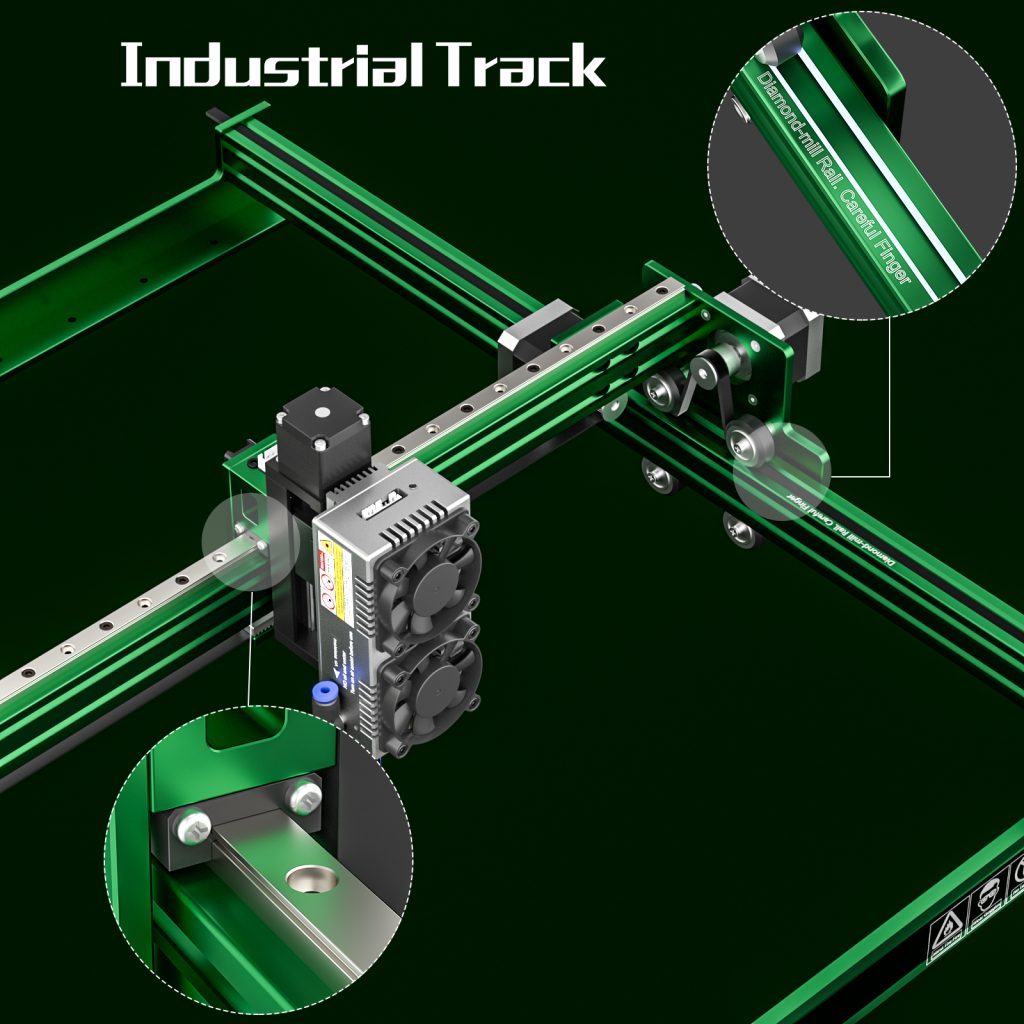

- The repeated positioning accuracy of Y and Z axes reaches 0.001mm, XYZ axis includes automatic reset, and the repeated positioning accuracy after reset can also reach 0.01-0.001mm. The X axis adopts industrial linear track, and the Y axis adopts NEJE special design diamond tool to cut linear track, which has a longer lifespan and precision.

- The new Max 4 machine has industrial-grade structural accuracy. All parts are calibrated by high-precision industrial master machine, linear track correction, and the installation direction of each plane is precisely matched, making the operation of the module more accurate and stable.

- The machine has anti-jitter design, so there is no ripple in such a large area of lightweight equipment. NEJE can effectively eliminate the jitter of precision drawing by customizing alloy materials with different hardness and matching reasonable shock absorption design.

- The new built-in anti-static design will make the equipment more stable and reliable

- It is compatible with all 12V and 24V modules of NEJE (only E80 is 24V module at present) to realize the application of different materials and different process requirements

Relate post

- ALL-NEW Laser Rotary Attachment: Micron-level precision & One-handed operation

- Plywood Laser Cutting Tutorial: Step by Step – Snake Lantern

- NEJE laser engraver ideas——Zodiac Tailsman

- NEJE laser engraver ideas——Teapot storage

- NEJE laser engraver ideas——Mario refrigerator magnet

Topic

- Laser Rotary Attachment

- NEJE 3

- NEJE 3 Max

- NEJE 3 MAX V2

- NEJE 3 MAX V2 E40

- NEJE A40630

- NEJE A40640

- NEJE E40

- NEJE E80

- NEJE MAX 4

- NEJE MAX 4 A40640

- NEJE MAX 4 E40

- NEJE MAX 4 E80

- NEJE Max 4 Frame With Drawing Pen

- Plywood

- 未分类

Other support

- Acrylic

- Applications

- Canvas

- Ceramic

- Leather & Mirror

- Machine

- Materials

- MDF

- Module

- Plywood

- Slate

- Solidwood

- Stainless Steel & Metal

- Tile

how much does the rotating attachement costs?

https://neje.shop/products/neje-laser-engraver-individual-a-axis-rotary-module?variant=41101505364104

179$

Already bought and test amazing machine… satisfy!