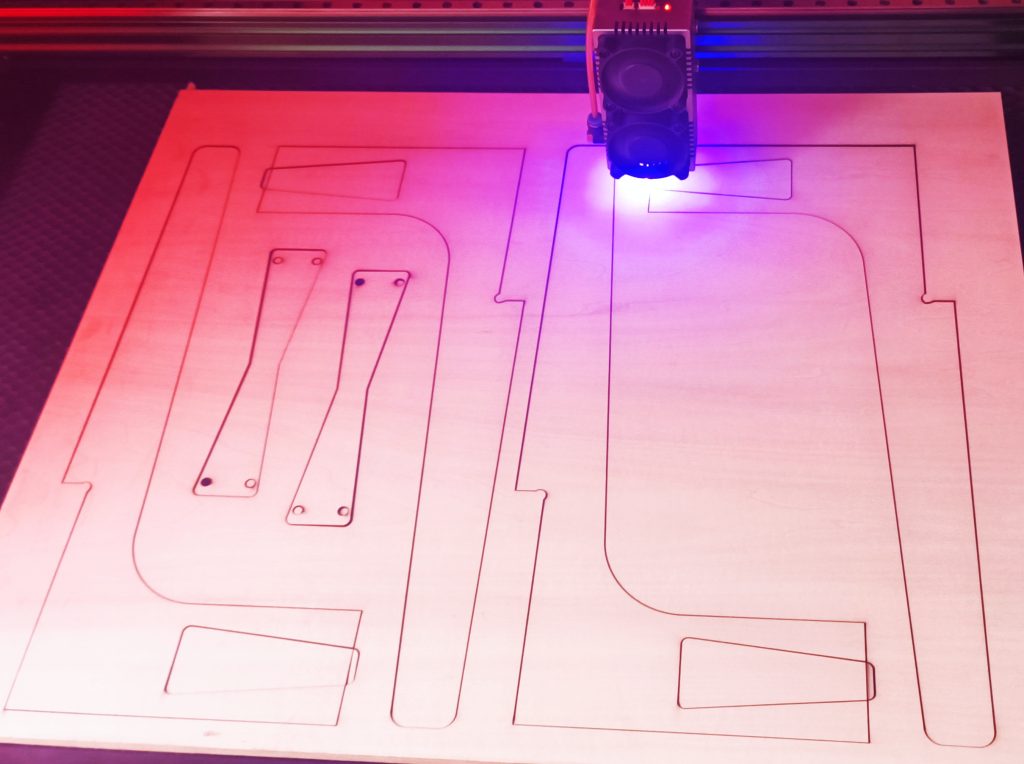

Machine &Module:NEJE 4 Max & E80

Material & Tools:10mm Plywood, 16 medium sizescrews, screwdriver or electric screwdriver

Method:After cutting and assembling, you have to align the screws with the cut circles to fix the chair.

The Idea You Can Get from this Post:

Tutorial Guide:

1.Pre-focus

Place the plywood and measure the focal length between the plywood and the E80 module to be 25mm. Please note that the production of this project does not require the user to adjust the size.

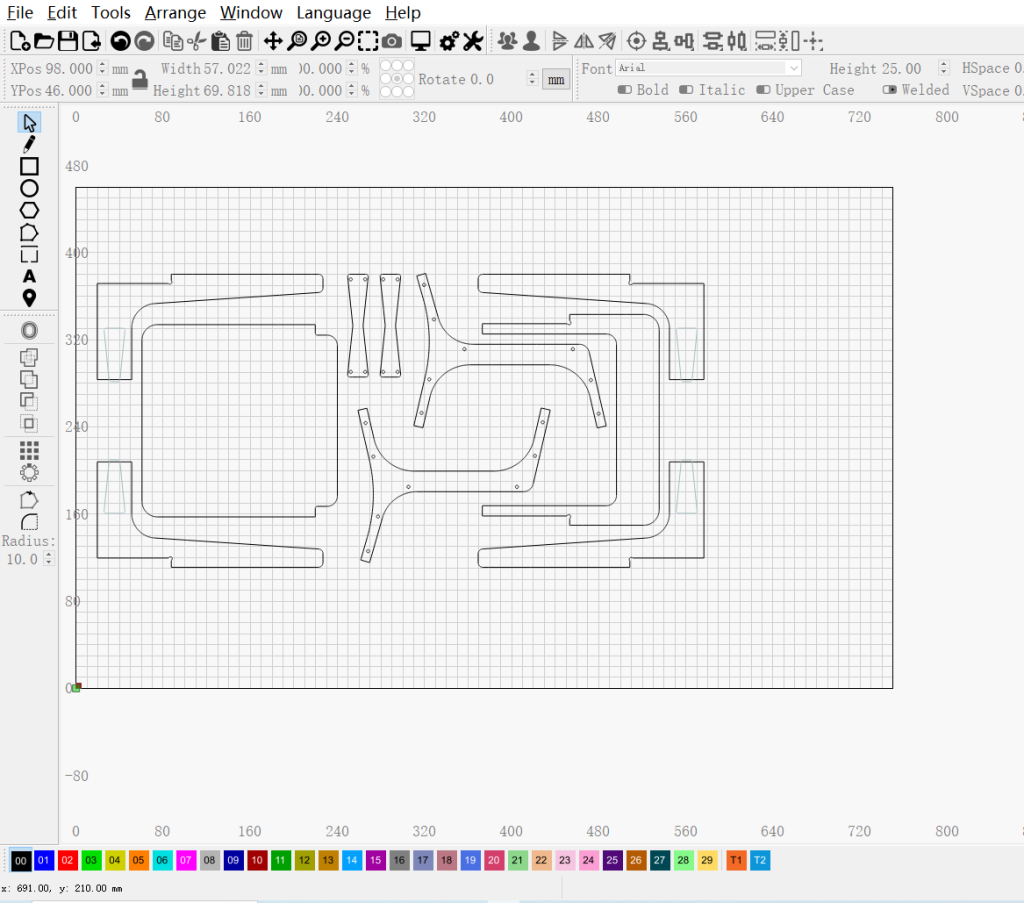

2.Upload the file

Connect the machine and open lightburn, upload the dxf file you downloaded to the lightburn application interface. If there is no extension rod, it is recommended to cut it in four steps and put it in one picture to facilitate customers to visually see these parts. In the file, we have divided it into four sections to facilitate the cutting operation.

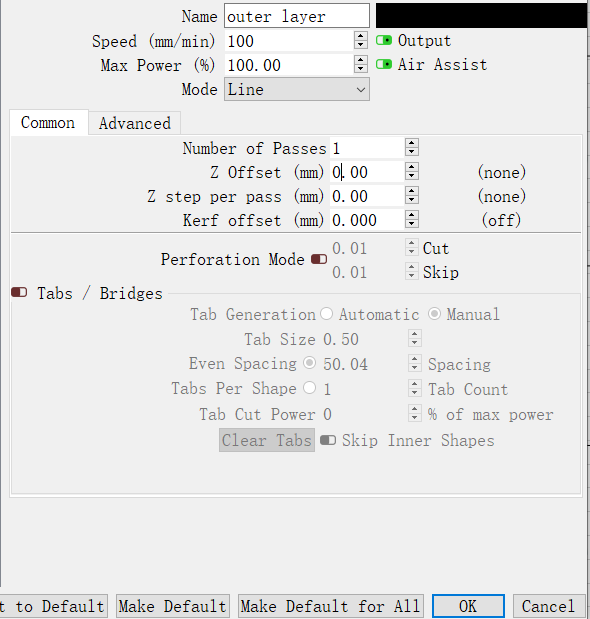

3.Settings in Lightburn

100mm/min, 100%power, 1 pass

If you cannot cut successfully, you can adjust the speed to 200mm/min, sink 2mm and then make two more cuts. Increasing the speed is considered to prevent the cutting surface of the material from being burned too severely.

4.Other instructions

When cutting thick wood, a large amount of wood dust will appear. Please start working in a closed environment with air assistance.

- ALL-NEW Laser Rotary Attachment: Micron-level precision & One-handed operation

- Plywood Laser Cutting Tutorial: Step by Step – Snake Lantern

- NEJE laser engraver ideas——Zodiac Tailsman

- NEJE laser engraver ideas——Teapot storage

- NEJE laser engraver ideas——Mario refrigerator magnet